Stocking Spreader Bar Materials

Material For Spreader Bars – What Should I Stock?

So you are setting up to build spreader bars and you are wondering if you should stock material and what types of material to stock before you start? This is a pretty common problem. Many people, especially when they start, don’t have a full-scale fabrication shop running and don’t necessarily have a need or the capital for a well-stocked steel supply. The good thing is for spreader bars you won’t need very many grades of steel; the bad thing you will need a number of different sizes.

Material Grades:

When you are selecting which grade of material to stock, it’s probably a good idea to start with reviewing what the engineer has specified. They should be specifying a material with around 50,000lb yield which can come in a variety of specs across the world. For tubing, I commonly specify a 50W (CSA G40.21) or ASTM A500 grade C because that is the most common structural steel. Both 50W and A500 are low carbon steel that have high weldability and a good track record for being a great material option. If you are operating outside of North America or are unsure about that materials, most good steel supply companies can help you find an equivalent steel as those listed above. Everyone in the steel supply industry should all be very familiar with those selections and able to help you. For plate steel, I generally use a 44w or equivalent grade but I stay away from the more common ASTM A36 because of the MTR issue. A personal favorite material of mine is quenched and tempered high tensile steel. I love designing with this material because it has a high strength to weight ratio and excellent material properties.

MTR

This brings me to the second important part when selecting and stocking materials, the MTR. The MTR can be called Material Test Record, Mill Test Report (or any number of variations) and is a document that is produced when a sample of that mill run (of material) gets tested or undergoes its quality control process. The quality control process and the tests done are governed by the standards the producer is trying to achieve. For instance, 44w has a different standard than A36 and each code specifies different required properties. If it meets that requirement, the material is officially that grade.

You can find and buy these standards such as http://www.astm.org/

Spreader bars are a structural piece of equipment that people rely on to keep them safe and therefore you should only utilize material that has some sort of documented quality control process and meets a known grade of material.

So back to why not A36? It is important when dealing with structural components that the MTR includes yield testing, elongation and performance at lower temperatures (especially important for Canada). This is not part of the ASTM A36 code but is part of the 44w or A500 codes. Now that I said that, it is common with A36 for the supplier to exceed the code and still do material testing but isn’t always the case so check to be sure.

MTRs also help prove traceability on your material which is an important feature if something ever went wrong and you needed to prove which material was used. So when you buy materials make sure there is an MTR and it is a good practice to have someone review the MTRs to make sure what you are getting is the same as what the engineer specified. At minimum you want to review yield strength but depending on what you are doing you might need a more thorough review. You should also keep your MTRs for several years after the project leaves.

Sizes:

The complex question is what sizes to stock. To make things easier I personally try and stay away from designing with I-beams. This is because there are so many versions and sizes that obtaining supply and stocking material can be very difficult. You also can’t do telescopic versions of anything with an I-beam so I will focus more on the tubing or hollow structural steel (HSS). When discussing HSS you need to consider the parameters of available lengths that come from the mill and which thickness you need for the design.

Lengths:

Most material will come in lengths of 20’ – 50’ and specific intervals such as 20’, 24’, 25’, 30’, and occasionally on some weird intervals such as 48’. But it changes from material to material and what your supplier has access to. When building spreader bars, you will inevitably need access to a wide array of tubing sizes and usually on short notice so it is important to develop a good relationship with your steel suppliers as soon as possible. All the different lengths also mean material utilization can be an issue. It always seems to happen that you land a great sale for 60ft long telescopic 50ton spreader bar and realize you need two 30ft lengths (approximately) to make each section but can only buy the material in 48 ft lengths. Which leaves you with 18ft of waste. All I can say is try your best to produce as few short sections of material as possible. If there are short sections you might consider making a smaller length beam for stock. I would recommend that you do a little exploration about buying material cut-to-size vs buying full lengths and trying to figure out what to do with the excess. Steel supply companies will always charge you a handling fee for cutting material to length but occasionally because they move a lot of material they could have a use for the offcut and it might end up being cheaper than putting it in inventory.

Thickness:

The strategy with thickness is balancing material sizes that will fit in each other for use with the telescopic spreader bars without requiring stock in every size. I use a couple rules of thumbs to make this easier.

- Pick a minimum size. For me, I don’t use material smaller than 2.5” tubing. This means on some of the small and light spreader bars the customer is paying for more material than is actually required but I also feel the longevity of using really small materials is jeopardized. This will simplify the number of sizes you need to stock and customers are rarely unhappy with getting a larger bar as long as your costs are reasonable.

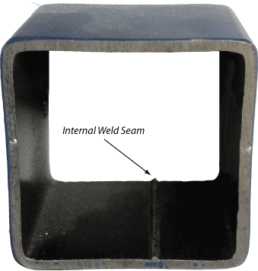

- Understand clearances. Hollow structural shapes (HSS) is generally rolled and welded at the factory into the square shape so there is a weld seam that runs down the inside of the tube. One lesson everyone learns in this industry is that paint + weld seam requires a lot of clearance. I borrowed this perfect picture of a weld seam from omega-bg.com

- Asses how often you are going to be producing high tonnage, long spread bars. 100 ton 60ft telescopic bars require some big material, but usually represent the smallest volume of sales. Do you really need to stock this material?

- Review and balance whether the risk of losing the sale because of lead time on the material makes it worth stocking at all. If you have a good supply of steel and customers that aren’t too demanding, I recommend not stocking material. Having said that, my experience is that most customers value a quick delivery more than price so this may be difficult if you end up losing days or weeks waiting for material.

- Use fewer material sizes. You can manipulate the design a bit in order to use fewer material sizes such as running two pins to get more pin surface area rather than increasing thickness.

When building telescopic spreader bars, increments of ½” with a 3/16” outside tube wall thickness work really well together for sliding. For instance, a 3x3x3/16” outside tube paired with a 2.5”x2.5” inside tube, slide really well once they are painted. Of course, the thickness of the inside tube will depend on the capacity and there is a limit to what the 3/16” outer tube can withstand before running into localized buckling issues. There are a few additional tricks and ways to handle clearances and sliding but I can probably write a full article on that so I will save that for another day.

I hope that gets you started in narrowing down which material to start stocking. Or even help you to decide if stocking material is the right move at all. If any of the terminology in this article was confusing check out the article: Anatomy of a spreader bar to learn more. If you enjoyed this article I recommend signing up for our newsletter (look to the right) so that you get notified when the next article comes out.

Digital Inspections

Digital Inspections:

Are you still writing your field inspection data on paper? Last time you looked into it did you find inspection software expensive, cumbersome and unable to match your process? Are you still asking what happens if I’m out of cell phone reception? Well, its time to look at software again because they have come along ways in the last few years.

Why You Need It:

I could go on for a long time writing about all the reasons you should be using a digital inspection system but I took my top 10 and made: 10 Reasons Why You Need Digital Inspections. In short its just a nicer experience for everyone. Your customers will love it for how polished and informative the field reports are, your office staff will love the reduced paper load and not having to transcribe data off paper reports. It will make your inspectors more efficient in the field with pre-filled out answers, access to historical data and premade inspection plans. And ultimately it improves your companies image, efficiency and bottom line.

What’s Out There:

There was a time when finding a good piece of software to do this was difficult. Now, it’s the opposite problem: There are so many different packages which is the best for me? I would loosely categorize the market into 3 categories: Do it yourself forms, inspection software and enterprise level software. In the do it yourself catagories you can find solutions using free Microsoft/google forms or one step up from that things like zoho which allow you to build your own forms but isn’t specifically dedicated for doing inspections. The next level up is where I think the most value lies. This is in software specifically designed for companies doing inspections for a living. Most of the software in this category aren’t specifically written for weld inspection companies but try and capture everyone from home inspectors to mechanics. Look for a good set of features and a reasonable price of around $10-20 per user. The enterprise level software is a little more expensive but can customize to your companies needs or come on a platform that has a lot of features. Sales Force, Field iD and any of the custom programmed options fall under this category. I don’t have a lot of experience with the larger more expensive software packages as most of my experience is at that middle level. If you want to spend the rest of the week reviewing and comparing software Capterra has a list of 138 different software packages ranked, reviewed and linked available here: https://www.capterra.com/inspection-software/.

Key Features To Look For:

Here are some of the key features I look for when shopping for this software:

- Off line mode for when no internet is available

- Compatible with what ever brand of cell phone you use.

- A way to push updated sheets out to all the users

- A good asset tracking system that you can use to look up historical data.

- Custom branded reports

- Some management tools to show inspections per week/month by user – which is great to make sure none of the invoices gets forgotten

- Built in scheduling system. If you have one person receiving calls and booking the inspection work why not keep that all in one system.

- Ability to email reports directly from the application.

A side note before you commit to any software make sure it is being sufficiently supported. You don’t want to get a year or two worth of inspection data in the software then find out when apple updates their phone the app stops working.

Personal Recommendation

I just thought I would take this opportunity to shout out to Inspectall which is the software I have used the most. Their software works great for smaller inspection companies doing weld inspection and equipment recertification. The treated me great over the years and have a good set of features. If anyone wants to skip the research or at least have a starting point I would certainly recommend starting at inspectall and compare anything else to it.

The Only Downside:

I have lots of positive things to say about digital app based inspection software but there is a downside. The biggest problem is that your inspectors will have their head buried in a cell phone a lot while on site. It looks like they are playing games rather than being productive. You will need to educate your customers that using the cell phone on site is actually improving the efficiency not slowing it down. Also, a few job sites wont allow cell phones on site for safety or security issues so you will need a plan b for situations that absolutely will not allow cell phones.

Thanks for reading this article. If you have any questions don’t hesitate to reach out to us. If you have a favorite inspection software let us all know down in the comments. If want to download a sample scissor lift report that you can use as a guide to set up your first digital inspection you can download one here. If you enjoyed this content and want to stay in touch take a second to join our mailing list so we can let you know when new content comes out.

Elusive Digital Inspection Exposed

10 Reasons You Need Digital Inspections

Inspection companies don't want you to share their inspection software because they are afraid of the competition. I am here to share my 10 reasons you should sign up for a digital inspection software now.

No Paper, No Pens

The first and probably most obvious part of going digital is the lack of paper and pen. If you have ever tried to write an inspection report in the rain, dirt or cold you know that it can be a struggle. What ends up happening is the inspection is done and the report is filled out in the truck afterwards. Go digital and update your report as your inspection proceeds. Your whole inspection report can sit in your pocket and come out when you are ready to change it.

Automatically Saving Documents

Never loose any work again. Automatically save in progress inspection reports but also never lose old reports again. Start an inspection one day, finish it another day even by a different person. All your reports can be saved digitally in one spot so you don’t have to rely on your inspectors being organized and keeping their paper together.

Deliver multiple copies

Deliver a copy of the field report to the supervisor, customer and engineer while you are still on site. No time delay between reviewing paper work and doing the paper work. Catch problems quickly and give everyone instant feedback

Auto generate numbers

Another great feature in digital inspection software is that you can automatically generate numbers if you want. Want a unique job number? Or inspection number? Let the software assign that number for you. Many engineering companies try and dole out certification numbers as a method of preventing the inspectors circumventing the process. That feature is built into most of the available programs and its all automated.

Embed pictures

If you want to impress your customers you need to embed pictures of the inspection inside the report. Show them pictures of problem areas embed proof of repairs even take a nice visual of the piece of equipment so they know what unit it is. Do this all in the field with a click of a few buttons. Pictures get included without the need to add them manually.

Digital Stamps

Pair the digital inspection with a digital engineering stamp & certification and throw the printer in the garbage

Historical Data

Keep all the historical data on a piece of equipment at your finger tips. Save time by not having to write out customer, unit number etc when re-inspecting. Check back to make sure they followed up on old issues and more. You can essentially have access to every inspection ever done by your company from your phone. I found the especially useful when a customer would phone and need another copy of a report you could easily look it up and send it to them again right from your phone.

Templates

Make sure your reports look uniformed and professional by using predefined fields. Use check boxes, pre written answer and other formatting tools to make sure all your reports fit your companies image. Use pre-planned reports as a way of guiding your inspectors through the inspection. Easily check to see if the inspector forgot something. Use a different template for each type of job.

Consistent Reports

Make sure your reports look uniformed and professional by using predefined fields. Use check boxes, pre written answer and other formatting tools to make sure all your reports fit your companies image. Use pre-planned reports as a way of guiding your inspectors through the inspection. Easily check to see if the inspector forgot something. Use a different template for each type of job.

Save Time and Money

It wasn’t too long ago that inspection software was custom and expensive. That isn’t true these days. You can easily offset the monthly cost of the inspection software by saving time on paper work. Eliminate the evening and weekends catching up on paper work and stop transcribing data off a report onto a computer.

I can’t stress how important I think this is. I shake my head every time I see an carbon copy hand written inspection report. This was a two part article you can read Part 1: The Elusive Digital Inspection System. if you are ready to get started inspecting and want an example inspection report (to copy into your new software) Free Inspection Report Download. If you want hear more about my thoughts on how to structure an inspection company let me know in the comments.

5 Questions Equipment Inspectors Should be Prepared to Answer

If you are preparing to solicit new business for your weld inspection company get ready to answer these 5 questions.

Do you have an Engineer on Staff or Contract?

Yes or No and get ready to tell them why its better that way

No surprise that my first point is on engineering. Customers will want to know you have access to engineering and will often ask this by saying “do you have an engineer on staff”. This is a bit of a loaded question because there are a bunch of assumptions about the level of engineering support you get if if you have an engineer on staff. If you can simply answer yes, great! Tell them about your available engineering service. If you don’t, you will need to convince them that not having an engineer on staff is an advantage not a disadvantage. Whether or not you have an engineer on staff or not try these talking points:

- "I have access to an engineer on the phone anytime during the day to walk through any problems while the inspection is getting done."

- "If we need it my engineer can make a site visit to review more complex problems."

- "The turn around time on engineering documentation is ___________ (1 day, 1 week, 1 month)"

- "My engineer has the following experience.."

- "Ontop of equipment recertification we can offer you the following engineering services: reverse engineering, weld repair instructions, failure analysis, part design etc."

Do you know what you are doing?

Have a plan and show it to them

There are two types of inspection services out there. There are weld inspectors and there are companies that offer equipment re-certifications. Your potential customer will have experience dealing with people from both camps. The problem is that it is common for weld inspectors to come out of industry like pipeline inspections when it is slow and dabble in crane recertification’s. The major difference between the two groups is that weld inspectors get told what to inspect how much to do. Equipment inspectors come with a plan. Be prepared to show your potential customer that you have a plan and what that plan is. My strategy was to always walk in the door with a complete inspection report for a piece of equipment similar to what they had. That way I would show I had a plan and some experience doing that kind inspection. Click here if you want to download an example inspection sheet.

The company I’m using now has been really good – what are you doing different?

Make them a priority in your schedule

The problem with acquiring customers in this industry is that the customer that switch to using you easily and quickly will also switch again when the next guy walks through the door. You want to try and acquire the loyal customers which are, obviously, hard to get. You will need to sell your level of customer service because that is usually what keeps customers. My favorite trick was to tell them you have 24h service. This usually gets a great reaction without much risk on your side. Rarely will the guy you are talking to work 24h a day so why would they need inspection services? Not to mention you can always charge overtime if they do call you late at night or on the weekend.

However, the critical question they will want to know is how soon you can do inspection or how far you are booked out. Potential clients always ask this question because so few companies are organized enough to plan their inspections weeks in advance and get them booked with the inspection company. Usually, it is all last minute. If you are a startup with no work this is easy to answer since you can literally come immediately but as you grow you will need a more defined strategy for this. I always felt that keeping the inspectors at 80-90% capacity always left room to fit in a new customer or adjust if there was scheduling problems.

What are your rates?

Play up the service play down the price.

The dreaded question. We all hate to compete on price but often that is the most common question the customers focus on. I have found that people ask this question because price is the easiest way for the customer to differentiate services and it is easy to talk about (for them) and easy to compare. I however, don’t feel customers leave current service providers because of price alone. It is usually paired with bad services, slow service or them feeling cheated somehow. I recommend focusing on the services you are offering rather than the price itself. For instance, do you charge for travel, what about call backs? Another strategy I use is to try and make a bit of partnership on price by telling the customer they can greatly influence the efficiency of the inspection and the price per unit if they are properly prepared for you with clean equipment already set up for inspection or by having multiple units ready to go at one time. Go into the meeting with a good idea of what your prices are and be confident in them. After all, if the average inspection is in the neighborhood of one day rental rate on this equipment and the customer is renting it out the other 365 days a year is the 0.27% of gross cost really the issue.

The Un-Asked Question: Image & First Impressions

Work on that professional image.

This is not really a question but I think in this business image speaks volumes. You are asking the person you are meeting to make a judgement call on you personally as well as your company so make sure you show up with a polished “appropriate image.” This doesn’t mean show up in a slick suite but make sure you are have clean cloths on and you didn’t just come from your last job. Make sure your vehicle is in good shape, clean and well identified. Have business cards ready and something you can leave with the person you are meeting. I had success leaving a booklet with them that was more than just some sheets stapled together so that it doesn’t get lost on their desk. Show up with the proper personal protective equipment so you can suggest having a discussion while you get a tour of the facility so it is more of a casual conversation for both parties. You can try different things and you will get a feel for how formal of a place you are walking into once you get through the doors.

However, always keep your coveralls and equipment in the truck in case they give you a chance to do a inspection on the spot.

New Blog:

Welcome to the Basepoint Blog.

Welcome to the Basepoint Engineering Blog. This introduction post is meant to provide a guideline to everyone interested in what our plan is. We plan on posting interesting articles weekly about the things we are working on and thinking about. If you are interested in staying in touch take a second to join our mailing list so we can notify you about new content. We will primarily be focusing on the three areas listed below:

Lifting Equipment:

We have years of experience working with all types of lifting equipment. Everything from designing below the hook lifting equipment as per ASME B30.20 all the way up to building derricks for service rigs and drillings rigs. Basepoint will have a strong focus on below the hook lifting devices as this is a personal interest of mine. I believe the limiting factor in the lifting equipment business is often the engineering and so I see an opportunity to be in this space providing information and engineering support to operators and manufacturers. Over time, we will be releasing a series of articles and products to help people start building spreader bars and other lifting equipment either for themselves or to sell for profit. Eventually, I hope to have a fully stocked online store of drawings for download. Spin off services for lifting equipment will include inspection, reverse engineering and custom design of lifting equipment.

Structural Inspection:

In Canada most equipment that lifts a person or lifts something over a person needs to be inspected annually and that inspection requires a review and certification stamp by an engineer. We will be offering structural inspection certifications along with information in the industry right across Canada. Our goal here will be to capture 1-5 person inspection teams that maybe are not big enough to have in house engineering and provide them exceptional third party engineering support.

Custom Engineering:

Most of our career has been spent building custom equipment. This has revolved around mostly the oilfield where we built fracking and pumping equipment, service rigs, drilling rigs, catwalks and more but also in other industries working on commercial trailers, structural products and even the odd agricultural project. At Basepoint we plan on continue this tradition offering our service to design pretty much anything you want. We come from the unique perspective of seeing and working on a variety of equipment allowing us to be comfortable working with pretty much any design. Our approach to all design projects is more of a partnership where we expect the customer to bring a deep knowledge of the product and how its used and we can compliment that with engineering and a designing process that makes for efficient manufacturing.

If that sounds interesting to you then take a second to subscribe to our updates.

Basepoint is going to approach engineering a little differently than most firms. Our focus is going to be providing ready made solutions online rather than a custom experience and custom solution to every problem. Our hope is that we can design products in a really efficient way and spread the cost across many customers reducing the overall price for everyone. We as a company value location independence and opening an office is not in our business plan. We also believe that the engineering sector is underrepresented on the web and plan to make web based engineering a major focus of ours.

Thanks for checking in on our new project and coming with us on this journey. Let me know what you think in the comments.