There are many different styles of lifting beams out there. Over the years many people have tried to innovate on the simple idea of a beam that spreads the lifting points out from a single crane hook. Here are a few options to think about if you are considering purchasing a lifting beam. Before you start consider doing some background reading on lifting equipment: 10 Things To Consider Before Building Lifting Equipment

Standard Beam:

This is the most basic option. It has one center pick point that can be used with a shackle or cut into a loop to fit directly onto a crane and has 2 pin on swivel hooks on the ends. A simple and effective version of the lifting beam. These device is usually made from cut and welded I-Beam.

The Bolt Together Version:

Lifting beams lend themselves to a weld free design by utilizing two channels either structural or formed bolted together with the lifting lugs sandwiched in-between. This style is one of my favorites because of the customizable nature, adjustability and lack of welding. In many cases it is easier to cut flat plate and bend it into two channels than buy a specific I-beam size because there is less wasted material from having to buy stock lengths of structural steel.

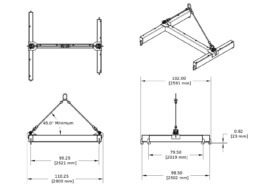

The H beam:

Im guessing this got its start lifting shipping containers but this style of lifting beam looks a lot like three beams attached together. The idea is that you have a large square four sling lifting system that doesn’t apply sling pressure to what ever it is lifting. I often see this style used with bulk hauling bags or lifting engine/generators skids. I have seen and built many different versions of this bar including under-slung over slung, bolt together, welded etc. The one picture to the right was a special low temperature version we built that had unequal leg lengths and made from formed low temperature rated steel.

Plate Lifters:

Not to be confused with clamps used for lifting plate steel these lifting beams are smaller in size and usually high capacity lifting beams cut from a single piece of plate steel. Some times they have stiffeners to improve out of plane bending sometimes not. These beams are loved by manufacturers because they only require one cutting process then are ready to work but I find many engineers forgetting to ensure that out of plane bending is addressed.

Adjustable Lifting Beams:

Many different attempts have been made to make an adjustable lifting beam. Some systems have movable lower rigging points. Some just have multiple lugs across the top or bottom. Both systems are trying to give more versatility to the end user. The one shown to the right just has multiple lower holes which I think is the simplest way to get the job done.

Why Choose Basepoint:

If you are considering purchasing a lifting beam take a second to consider buying from us. Tap into our years of experience designing and building lifting equipment. We provide manufacturing drawings on our online store that you can purchase and download today. We can also supply a quote with a finished product as well. If you are thinking about starting but want to chat with someone first you can reach out to us here.