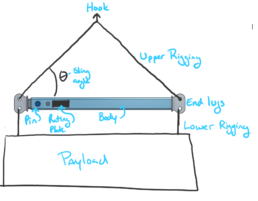

As an engineer who operates in a number of different industries one of our biggest struggles is to get up to speed on the industry specific terminology and learning the field names of equipment and processes. Lifting equipment also suffers from this as we also have a specific way of referring to different parts of a spreader bar that has been developed over the years. I thought it would be a good idea to share the lingo with the readers in case there is ever a situation where a term is used that isn’t understood. Hopefully this will stop the need for clarifying the lingo in further articles as well.

Upper Rigging

The upper rigging is a generic term used for all lifting equipment that is above the spreader bar but below the crane hook. This includes the shackles, cables or chains, master-link if there is one etc. Some spreader bar manufacturing companies sell the spreader bar with the upper rigging included because it is usually specifically sized to maintain a load rating. For instance the loading on the spreader bar changes a lot depending on length of rigging because it can change the sling angle and it can be tricky to get the right capacity on the upper rigging because the required trigonometry to figure out the load. However, if you have or want to source the upper rigging you should be able to source a local rigging supply company for manufactured slings and some of the components such as the shackles will come from one of the big equipment manufacturers such as Crosby.

Lower Rigging

The lower rigging is any rigging or equipment that gets attached below the spreader bar. This can include a wider variety of equipment than the upper rigging as there are many widgets that can be used to help connect the spreader bar to the payload. The lower rigging is usually handled by the end user not the spreader bar manufacture unless there is a scenario where specific rigging is required. The sum of the load on either side of the lower rigging should be vertical or near vertical so specifying the lower rigging tends to be a lot easier to figure out and more situational.

Sling Angle

This is the angle between the spreader bar and one leg of the upper rigging. This is a very important parameter because as the sling angle gets smaller the loads in the spreader bar and rigging increase. The sling angle or at least a range of sling angles are generally specified by the manufacture or engineer and shouldn’t be changed. It is most common to see 45 degrees or 60 degree sling angles.

Rating Plate

According to ASME B30.20 each spreader bar needs to have a permanent rating plate on it. These rating plates should show who manufactured the bar, the capacity, the design category, service class and a few other things. This is one of the most commonly forgotten items that we run into in the spreader bar world. Rating plates are often skipped by do it your-selfers as they can be hard to manufacture without some specific and expensive equipment.

Pin

On the telescopic variety of spreader bar there will be a pin that is used to set the length of the beam and is a pretty straight forward piece of equipment. It is generally the first thing on a spreader bar that gets lost or damaged. Always check required material before replacing one as it is generally made from higher quality steel.

Labels

Each spreader bar should have a set of labels and decals to show capacity and some safety warnings. There are parameters regarding what these should say in B30.20.

Payload

I decided for the sake of clarity in my writing to call the object being lifted as the payload. I would say this isn’t typical industry terminology but when you are talking about engineering “loads” and payloads in the same sentence it helps differentiate the two.

Thanks for reading this article and hopefully we are all on the same page with how to talk about spreader bars now. I will probably update this document every time a new term comes up but for now it is what it is. If you enjoyed the article and want to receive more update from us please take a moment to sign up for our mailing list. If you are just starting your journey into manufacturing spreader bars you should read this article next: An Introduction to Stocking Materials for Spreader Bars.

[…] Anatomy Of A Spreader Bar […]

[…] Anatomy Of A Spreader Bar […]

[…] Anatomy Of A Spreader Bar […]