Ready to start building lifting equipment? Give these 10 points some thought! I had written this specifically as a summary to my 10 week course by email about building spreader bars and other lifting equipment but I thought it was too good to keep it locked up for only people that made it through the 10 weeks. I hope you enjoy this breife article and take the time to dive into some of the supporting articles.

Choose a type of lifting equipment:

The first step is to figure out what you need. If you are new to lifting equipment you can consider reading about the anatomy of a spreader bar to bring yourself up to speed on some of the lingo. But the first thing to decide is if you need a spreader bar, lifting beam or something total unique and custom. Review your requirements and address how important the following features are: maximizing head height, cost, load balancing, transport-ability.

Choose a manufacturing style

Now that you know what style of device you need the next step is to chose a style of manufacturing. Is it going to have high tensile steel? or does it need Two pins or one? If you are building a spreader bar you need to choose a style of end connection and whether or not you need spacer plates on the telescopic surfaces. If you are building a lifting beam you need to decide if you want I-beams with lugs welded on it or a weld less system consisting of two channels or even one made of a single heavy plate.

Consider Operating Conditions:

There are three operating conditions that are important to consider before you finish the design of your spreader bar or lifting beam. The first is environmental conditions. Here you should be considering if you are using the lifting device outside where extreme heat or cold could compromise the equipment. Is the beam being used near a smelter giving off heat or out on the ocean where corrosion is a concern. The second condition is how unknown environmental factors, such as wind, load instability, operator set up, will be taken into account. This is important when selecting a design category as the more unknown factors the higher the category and more safety factor is required. The last operating condition looks at the life span of the lifting device and how many cycles it will see during its expected life. If you want to read more how to specify lifting equipment rated for cold temperatures you can read this article: Cold Temperature Rated Lifting Equipment.

Get Engineered Blue Print

You need to comply with the design code of BTH-1. That means your drawings need to be engineered. They also should contain the following: engineering stamp, weight of the device, the rated capacity, manufacturing specifications as well as the design category and service class. If you need engineered drawings you can find them at the Basepoint Store.

Order/Stock Material:

Have you thought about if it is more efficient to stock material or order on a job by job basis? You might be surprised after reading Stocking Spreader Bar Material that stocking materials for lifting equipment isn’t so bad. While you are thinking about what material to order you need to be prepared to deal with MTRs. A MTR, or material test record is a report that comes with a steel purchase that shows that the material being purchased meets the grade requirements for a specific code. For the structural steels you are probably using to build lifting equipment these will include a minimum yield along with a few other properties. It is highly recommended that you get the MTRs reviewed by a qualified person. As the manufacture the mtrs need to be saved and cataloged by job for future reference.

Have a qualified manufacturing process

Each country will have their own structural welding code. ASME B30.20 specifies the use of AWS D14.1 but in Canada we generally specify CSA W59. Both of those codes are full of good information and worth understanding if you are serious about building steel structures. The main concept that manufacturers will need to understand and utilize is the idea of validation and verification as well as the use of pre-qualified weld procedures vs ones that need qualification. AWS D14.1 also has a great section on adjusting your manufacturing procedure based on fatigue limits and matches up really well to the requirements of BTH-1 in relation to total number of cycles.

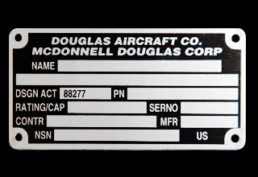

Make a rating plate

Rating plates are the most common piece to forget. ASME B30.20 requires a that a permanent rating plate is attached to the device listing: weight of the device, manufacturer information, rated capacity and design category and service class. The rating plates are often laser etched or machined and the information should be on the engineered drawing. If you are curious about rating plates check out this article: Rating Plates

“borrowed from Express: https://www.expresscorp.com/Industrial-Nameplates/Industrial-Nameplates “

7. Post construction testing

B30.20 and BTH-1 states that lifting equipment “should” be tested. Some suppliers in the industry claim to load test every spreader bar some don’t. Some customers specifically require a pull test and others don’t. I often recieve the question about whether you really need to pull test your lifting equipment? Find out by reading about pull testing.

There is an art to building spreader bars and all lifting equipment. Hopefully this gives you the resources you need to be OSHA and OH&S compliant. If you have any questions of comments feel free to reach out.

Jason Thompson

[…] Building OH&S and OSHA Compliant Lifting Equipment […]